www.wimb.net - Powerstats

POWERSTATS

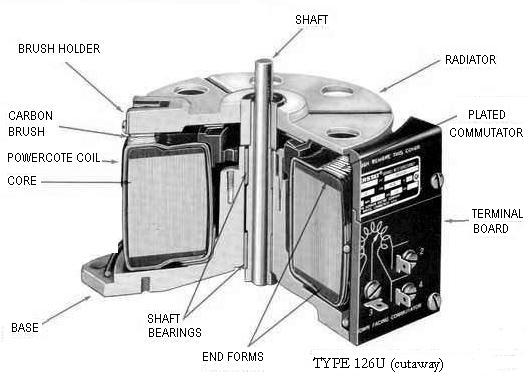

Most POWERSTAT Variable Transformers feature POWERKOTE coils for longer life, increased ratings,

greater overload capacities and better resistance to fungus, salt spray and other

contaminating atmospheres.

The commutator of the new POWERKOTE coil is

embedded in a high temperature material which holds the windings in place,

even under severe overloads. As a result, POWERSTAT Variable Transformers

with POWERKOTE coils provide higher output ratings per pound and per dollar

than ordinary variable transformers.

RUGGED MECHANICAL CONSTRUCTION

All POWERSTAT Variable Transformers are designed for heavyduty, trouble-free operation. Rigid inspection at every stage of manufacture gives assurance of a quality-built product. The securely mounted core and coil, extra large aluminum brush heat radiator and durable brush assembly reduce the need for attention or replacement.

EXCELLENT REGULATION

POWERSTAT Variable Transformers deliver the desired voltage with only negligible variation in output voltage from no-load to full-load current. Individual regulation curves are shown for all types.

HIGH EFFICIENCY

The watts loss of every POWERSTAT Variable Transformer is very low in contrast to the inefficient, wasteful control provided by rheostats and other resistive type controllers.

NEGLIGIBLE WAVEFORM DISTORTION

A POWERSTAT Variable Transformer provides an output voltage which is a faithful and distortionless reproduction of the applied input waveform. This is a required feature of many electronic applications and is a result of superior core and coil design and the use of highest grade silicon steel.

PRECIOUS METAL PLATED COMMUTATOR

A special precious metal plating process produces a commutator surface that withstands greater overloads and maintains a constant contact drop. The plated surface assures smooth performance, long life and increased resistance to corrosion.

EASY INSTALLATION

All arrangements for mounting and electrical connections are designed for user convenience. Terminals on all units are easily accessible and are of screw, lug, quick-connect or solder design.

OVERLOAD CAPACITY

Because of their conservative ratings and the use of POWERKOTE coils, POWERSTAT Variable Transformers can safely handle many overloads. The "on" curve in Figure A shows the maximum time the units can be subjected to various overloads. When used with repetitive overloads, the units must also be allowed sufficient "off" time as indicated by the "off" curve to prevent excessive temperature buildup. Where the "on" time desired fora repetition overload is less than the maximum shown, the "off" time can be reduced in accordance with the following equation:

DUAL INPUT

Most 240 volt POWERSTAT Variable Transformers have a lower input voltage tap that permits operation from a 120 volt input to obtain an output voltage of 0-280 volts. The output current must be reduced according to the curve in Figure B when the output voltage exceeds 125% of the input voltage.

NEGLIGIBLE MAINTENANCE

With ordinary care and attention to the operating instructions, the only elements that may require periodic inspection and maintenance are the brushes. Their replacement is infrequently needed because they are made of a special carbon and are of a design that assures perfect contact of the brush to the commutator at any setting.

LOW OPERATING TORQUE

The glass-smooth commutator surface, the constant and correct contact pressure of the brush-tap to the commutator and the stable positioning of coil and internal components result in the low operating torque of all POWERSTAT Variable Transformers. The driving torque for the individual units is given in the section devoted to the particular type.

TEMPERATURE

The average temperature rise for POWERSTAT Variable Transformers is 55ºC above ambient under continuous operation. The ratings given in this catalog are for operation at ambient temperatures of -20ºC to +50ºC at full rated load. When operation is required in ambient temperatures higher than 50ºC the output current must be reduced according to the curve shown in Figure C.

LINEAR OUTPUT VOLTAGE

The angle of rotation from zero to maximum output voltage is given for each POWERSTAT Variable Transformer in the section devoted to the particular series. Output voltage is continuously adjustable from zero to maximum output voltage proportionately over the full range.

SMOOTH CONTROL

The output voltage of a POWERSTAT Variable Transformer can be considered continuously adjustable. The voltage between turns is a fraction of a volt and the brush-tap is always in contact with one or more turns of the winding. Adjustment of output voltage can be made to a fraction of a volt.

LONG LIFE

POWERSTAT Variable Transformers give reliable performance over extended periods of time even under extreme operating conditions. Materials are constantly being improved to give increased life expectancy.

TERMINOLOGY

To permit maximum utilization of POWERSTAT Variable Transformers, output ratings are given for both constant current and constant impedance loads.

CONSTANT CURRENT LOAD:

Output current that can be carried regardless of output voltage setting.

CONSTANT IMPEDANCE LOAD:

Loads such as incandescent lamps or resistance heaters in which the current drawn is approximately proportional to the applied voltage, increasing to maximum current at line voltage. These ratings apply only to units having maximum output voltage limited to line voltage.

Links: Slo-Syn and Superior Electric

Updated 2007 Oct. 09